Sandbox Reserved 1846

From Proteopedia

(Difference between revisions)

| Line 36: | Line 36: | ||

To improve the catalytic activity and thermostability of LCC, Tournier et al. (2020) used structure-guided enzyme engineering based on the crystal structure of LCC bound to a model PET substrate.<ref name="Tournier"/> Using [https://en.wikipedia.org/wiki/Docking_(molecular) molecular docking] and enzyme–substrate contact analysis, the researchers identified 15 residues in the first contact shell surrounding the substrate-binding groove. Of these, 11 positions were selected for [https://en.wikipedia.org/wiki/Saturation_mutagenesis#:~:text=Saturation%20mutagenesis%2C%20or%20site%20saturation,amino%20acids%20at%20the%20position. saturation mutagenesis] to determine how mutations could affect PET depolymerization. These sites were chosen for their interactions with the PET-like ligand or their proximity to the active site. Highly conserved residues essential for catalysis or structural stability were excluded. | To improve the catalytic activity and thermostability of LCC, Tournier et al. (2020) used structure-guided enzyme engineering based on the crystal structure of LCC bound to a model PET substrate.<ref name="Tournier"/> Using [https://en.wikipedia.org/wiki/Docking_(molecular) molecular docking] and enzyme–substrate contact analysis, the researchers identified 15 residues in the first contact shell surrounding the substrate-binding groove. Of these, 11 positions were selected for [https://en.wikipedia.org/wiki/Saturation_mutagenesis#:~:text=Saturation%20mutagenesis%2C%20or%20site%20saturation,amino%20acids%20at%20the%20position. saturation mutagenesis] to determine how mutations could affect PET depolymerization. These sites were chosen for their interactions with the PET-like ligand or their proximity to the active site. Highly conserved residues essential for catalysis or structural stability were excluded. | ||

| - | From this screen, two mutations at Phe243 (F243I and F243W) were shown to improve catalytic activity by optimizing substrate positioning within the groove. To increase thermostability, the authors targeted a region of | + | From this screen, two mutations at <scene name='10/1075247/Better_f234/3'>Phe243</scene> (F243I and F243W) were shown to improve catalytic activity by optimizing substrate positioning within the groove. To increase thermostability, the authors targeted a region of LCC that is structurally analogous to known divalent [https://en.wikipedia.org/wiki/Metal-binding_protein metal binding] sites in other cutinases. Instead of using stabilizing ions, which could complicate industrial degradation processes, a [https://en.wikipedia.org/wiki/Disulfide disulfide bridge] was engineered by mutating Asp238 and Ser283 to Cys residues (D238C/S283C). Additional thermostabilizing mutations were selected based on thermostability screening. Among these, Y127G improved the melting point without reducing activity. <ref name="Tournier"/> |

These mutations were combined to create multi-mutant LCC variants with improved activity and thermostability. The two most successful variants were: | These mutations were combined to create multi-mutant LCC variants with improved activity and thermostability. The two most successful variants were: | ||

| Line 46: | Line 46: | ||

=== F243 === | === F243 === | ||

| - | <scene name='10/1075247/Better_f234/3'> | + | <scene name='10/1075247/Better_f234/3'>Phe243</scene> is located 3.6 Å from the ligand. Two mutations at this position, <scene name='10/1075247/Better_f243i/2'>F243I</scene> and F243W, increase the catalytic activity of LCC. The F243I mutation inserts the smaller isoleucine whose side chain allows the ligand to sit closer. This reduces the ligand distance to 3.0 Å, improving substrate binding. The F243W mutation inserts the bulkier, nitrogen-containing aromatic side chain. Trp brings the ligand slightly closer at 3.2 Å and introduces potential for new interactions, such as hydrogen bonding or [https://en.wikipedia.org/wiki/Pi-stacking#:~:text=In%20chemistry%2C%20pi%20stacking%20(also,interaction%22)%20is%20electrostatically%20repulsive. π-stacking]. Both mutations result in improved catalytic performance. The F243I mutant shows a 27.5% increase in activity, while the F243W mutant shows a 17.5% increase, compared to the wild-type enzyme.<ref name="Tournier"/> |

=== Y127 === | === Y127 === | ||

Revision as of 20:01, 17 April 2025

| This Sandbox is Reserved from March 18 through September 1, 2025 for use in the course CH462 Biochemistry II taught by R. Jeremy Johnson and Mark Macbeth at the Butler University, Indianapolis, USA. This reservation includes Sandbox Reserved 1828 through Sandbox Reserved 1846. |

To get started:

More help: Help:Editing |

Leaf Branch Compost Cutinase

| |||||||||||

References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 Tournier V, Topham CM, Gilles A, David B, Folgoas C, Moya-Leclair E, Kamionka E, Desrousseaux ML, Texier H, Gavalda S, Cot M, Guemard E, Dalibey M, Nomme J, Cioci G, Barbe S, Chateau M, Andre I, Duquesne S, Marty A. An engineered PET depolymerase to break down and recycle plastic bottles. Nature. 2020 Apr;580(7802):216-219. doi: 10.1038/s41586-020-2149-4. Epub 2020 Apr, 8. PMID:32269349 doi:http://dx.doi.org/10.1038/s41586-020-2149-4

- ↑ 2.0 2.1 2.2 2.3 2.4 Sui B, Wang T, Fang J, Hou Z, Shu T, Lu Z, Liu F, Zhu Y. Recent advances in the biodegradation of polyethylene terephthalate with cutinase-like enzymes. Front Microbiol. 2023 Oct 2;14:1265139. PMID:37849919 doi:10.3389/fmicb.2023.1265139

- ↑ Lichtenthaler HK. The stress concept in plants: an introduction. Ann N Y Acad Sci. 1998 Jun 30;851:187-98. PMID:9668620 doi:10.1111/j.1749-6632.1998.tb08993.x

- ↑ Ueda H, Tabata J, Seshime Y, Masaki K, Sameshima-Yamashita Y, Kitamoto H. Cutinase-like biodegradable plastic-degrading enzymes from phylloplane yeasts have cutinase activity. Biosci Biotechnol Biochem. 2021 Jul 23;85(8):1890-1898. PMID:34160605 doi:10.1093/bbb/zbab113

- ↑ Kolattukudy PE. Biopolyester membranes of plants: cutin and suberin. Science. 1980 May 30;208(4447):990-1000. PMID:17779010 doi:10.1126/science.208.4447.990

- ↑ 6.0 6.1 6.2 6.3 6.4 Khairul Anuar NFS, Huyop F, Ur-Rehman G, Abdullah F, Normi YM, Sabullah MK, Abdul Wahab R. An Overview into Polyethylene Terephthalate (PET) Hydrolases and Efforts in Tailoring Enzymes for Improved Plastic Degradation. Int J Mol Sci. 2022 Oct 20;23(20):12644. PMID:36293501 doi:10.3390/ijms232012644

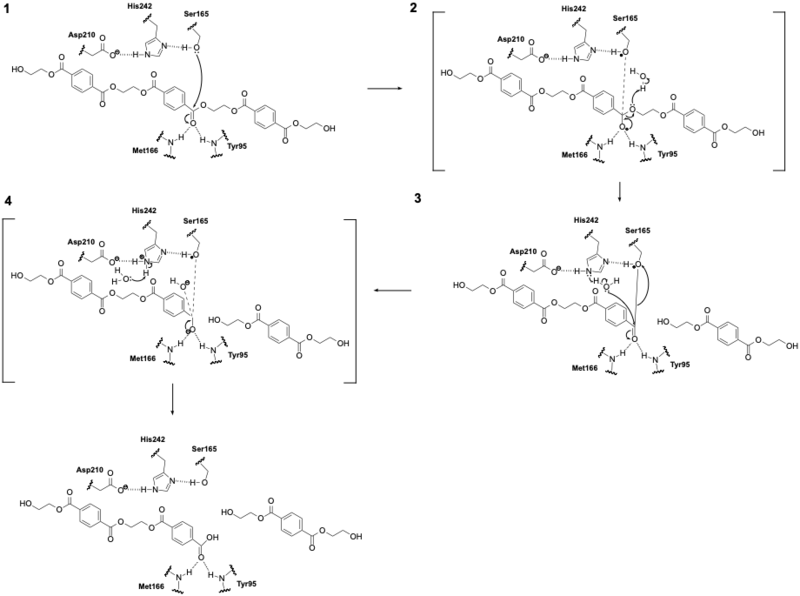

- ↑ 7.0 7.1 Burgin T, Pollard BC, Knott BC, Mayes HB, Crowley MF, McGeehan JE, Beckham GT, Woodcock HL. The reaction mechanism of the Ideonella sakaiensis PETase enzyme. Commun Chem. 2024 Mar 27;7(1):65. PMID:38538850 doi:10.1038/s42004-024-01154-x

- ↑ 8.0 8.1 8.2 Zhang J, Wang H, Luo Z, Yang Z, Zhang Z, Wang P, Li M, Zhang Y, Feng Y, Lu D, Zhu Y. Computational design of highly efficient thermostable MHET hydrolases and dual enzyme system for PET recycling. Commun Biol. 2023 Nov 9;6(1):1135. PMID:37945666 doi:10.1038/s42003-023-05523-5

- ↑ Yoshida S, Hiraga K, Takehana T, Taniguchi I, Yamaji H, Maeda Y, Toyohara K, Miyamoto K, Kimura Y, Oda K. A bacterium that degrades and assimilates poly(ethylene terephthalate). Science. 2016 Mar 11;351(6278):1196-9. doi: 10.1126/science.aad6359. PMID:26965627 doi:http://dx.doi.org/10.1126/science.aad6359

- ↑ Landrigan PJ, Stegeman JJ, Fleming LE, Allemand D, Anderson DM, Backer LC, Brucker-Davis F, Chevalier N, Corra L, Czerucka D, Bottein MD, Demeneix B, Depledge M, Deheyn DD, Dorman CJ, Fénichel P, Fisher S, Gaill F, Galgani F, Gaze WH, Giuliano L, Grandjean P, Hahn ME, Hamdoun A, Hess P, Judson B, Laborde A, McGlade J, Mu J, Mustapha A, Neira M, Noble RT, Pedrotti ML, Reddy C, Rocklöv J, Scharler UM, Shanmugam H, Taghian G, van de Water JAJM, Vezzulli L, Weihe P, Zeka A, Raps H, Rampal P. Human Health and Ocean Pollution. Ann Glob Health. 2020 Dec 3;86(1):151. PMID:33354517 doi:10.5334/aogh.2831

- ↑ Jambeck JR, Geyer R, Wilcox C, Siegler TR, Perryman M, Andrady A, Narayan R, Law KL. Marine pollution. Plastic waste inputs from land into the ocean. Science. 2015 Feb 13;347(6223):768-71. PMID:25678662 doi:10.1126/science.1260352

- ↑ Austin HP, Allen MD, Donohoe BS, Rorrer NA, Kearns FL, Silveira RL, Pollard BC, Dominick G, Duman R, El Omari K, Mykhaylyk V, Wagner A, Michener WE, Amore A, Skaf MS, Crowley MF, Thorne AW, Johnson CW, Woodcock HL, McGeehan JE, Beckham GT. Characterization and engineering of a plastic-degrading aromatic polyesterase. Proc Natl Acad Sci U S A. 2018 Apr 17. pii: 1718804115. doi:, 10.1073/pnas.1718804115. PMID:29666242 doi:http://dx.doi.org/10.1073/pnas.1718804115

Student Contributors

Ashley Callaghan, Rebecca Hoff, & Simone McCowan