User:Marius Mihasan/Sandbox 1

From Proteopedia

Contents |

Proteopedia and 3D Printing

Physical molecular models, by engaging both visual and tactile senses, provide an effective means of deepening the understanding of complex concepts in molecular biology and biochemistry. They allow students to perceive the three-dimensional organization of macromolecules, thereby enhancing comprehension of the relationship between structure and function [1] [2]. Numerous studies have demonstrated that the use of tangible models in science education improves learning outcomes, fosters conceptual reasoning, and increases student engagement [3] [4] [5]. The rapid development of 3D-printing technologies has made it possible to create customized and affordable molecular models [6] [7] [8].

Affordable desktop 3D printers can now be used to fabricate physical models from virtually any structure or scene on Proteopedia. This page provides an introduction to 3D printing, a step-by-step guide to generating printable files directly from Proteopedia, and several tested printing profiles for common printers (e.g., Prusa Research, Bambu Lab, Creality, or Elegoo).

Let’s 3D-print the whole Proteopedia!

Introduction to 3D printing / 3D Printing 101

3D printing, also known as additive manufacturing, builds physical objects layer by layer from digital designs. For more technical details please head for the excellent introductory article on All3DP. In structural biology education, 3D printing provides an affordable and accessible way to transform atomic coordinate data (e.g., from PDB, MOL or SDF files) into tangible molecular models that can be observed, handled, and discussed in class or laboratory settings.

Printer Types: FDM vs. SLA/DLP

The two most accessible 3D-printing technologies that cen be used to create molecular models are:

- FDM (Fused Deposition Modeling)

This method extrudes a heated thermoplastic filament (such as PLA, PETG or TPU) through a fine nozzle, depositing successive layers that form the model. FDM printers have the advantages of low cost, easy maintenance, wide availability, and being capable of printing large and colorful molecular models. This technology has a few limitations, such as: visible layer lines, lower surface resolution, and less suited for very small or intricate molecular details.

- SLA/DLP (Resin Printing)

This technique uses liquid photopolymer resin, cured layer by layer with ultraviolet light. SLA/DLP printers have the advantages of a very high resolution, smooth surfaces and are ideal for compact and detailed models (e.g., small proteins rendered as surface, ligands, or symmetric assemblies). This technology has its own limitations, such as higher material cost, post-processing requirements (washing and UV-curing), and the need for careful handling of resin.

When choosing between FDM and SLA printers, model size and resolution are the key criteria: FDM is preferred for large, educational display models; SLA/DLP is optimal for small, precise structures.

While FDM and SLA/DLP are the most widely used technologies in educational and research contexts due to their accessibility, other additive manufacturing methods also exist—such as Selective Laser Sintering (SLS), PolyJet, and Binder Jetting—each employing different materials and curing mechanisms. These industrial-grade techniques can produce highly detailed or multi-material parts but are generally more expensive and less accessible for classroom use. For an overview of major 3D-printing technologies, see All3DP: Complete Overview of the Types of 3D Printers

Single- vs. Multi-Material Printers

Most entry-level desktop 3D printers use a single filament or resin, producing models in one color or material. However, multi-material systems (such as Bambu Lab AMS and its variants or Prusa MMU3) can simultaneously print multiple filaments, enabling color-coded domains, subunits, or ligands directly in one print. For complex color information, users can also apply post-print color coding (painting or labeling) or print separate parts and assemble them manually.

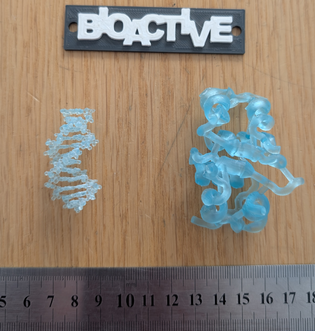

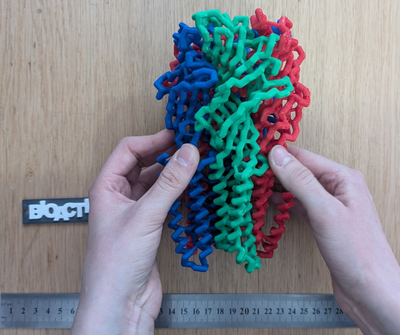

| A large FDM-printed model | A multi-material FDM-printed model | Small resin-printed models |

|---|---|---|

GABAA receptor, 6x3x |  Bacterial 70S ribosome, 4v5d | |

| Trace Model of the GABAA receptor printed on a single material FDM-Printer (Prusa MK3S+). Each of the 5 subunits was printed separately and can be assembled. Printable files available on Printables.com | Surface model of the Bacterial 70S ribosome printed on a multi-material capable printer (BambuLab X1C AMS). Blue and violet are ribosomal proteins, orange and yellow are rRNAs, and black is tRNA. Printable files available on Printables.com | Balls and sticks and cartoon models of DNA (right) and insulin (left) |

File Formats Used in 3D Printing

Proteopedia supports two export formats for generating printable molecular models:

- .STL (Stereolithography): the most common and universally compatible format; encodes only surface geometry, without color or texture information.

- .OBJ (Wavefront Object) with an associated .MTL (Material Template Library) files: includes both geometry and optional color/texture data; useful for color prints.

Another widely adopted file format used in 3D printing is the .3MF (3D Manufacturing Format): a modern open standard that stores geometry, color, and multi-material metadata in a single file—recommended for advanced printers. For a more extensive pros and cons of different 3D printing file formats please see The Main 3D Printing File Formats on all3dp.

STL is ideal for single-color models and maximum compatibility, while OBJ/MTL is recommended for multi-material workflows. 3MF files will be used in this tutorial to save the model and printing settings.

Overview of the 3D printing process

the path from structure/scene to physical object - including slicers and profiles From molecular structure to physical object Stepwise diagram (PDB → Jmol Scene → 3DP-Jmol export → STL/3MF → slicer → printer). Briefly explain what slicers are (PrusaSlicer, Bambu Studio, Cura, Chitubox, etc.). Emphasize the role of profiles (printer settings: layer height, infill, temperature, supports). Optional: add a short embedded animation showing a molecule being “sliced” layer by layer.

Generating printable files on Proteopedia

how to use the tool with screenshots, or maybe better, a movie? Step-by-step illustrated guide (with screenshots or a short video): Open any Proteopedia page and load a scene. Activate the Print3D tool (mention integration link). Choose representation type (cartoon, spacefill, surface, etc.). Adjust scale and export to STL/3MF. Notes on scaling limits, coloring, and how to combine multiple chains or ligands.

If possible, embed a short instructional video (1–2 min) —

Printing

This is where we provide printing profiles and instructions From file to physical model Provide tested printing profiles (e.g., downloadable .ini or .3mf files) for common printers: Prusa Research (MK3S, MK4, Mini) Bambu Lab (P1P, X1C) Creality (Ender 3, K1) Elegoo (Mars, Saturn – for resin printing). Include detailed settings for successful printing (layer height, infill %, speed, supports, post-processing).

Add example photos of successful prints from Proteopedia scenes (credit your lab or collaborators). Optionally: subsection on painting and finishing models for color or texture enhancement. - i do not do it, its not required. Maybe a link?

Other relevant resources

Curated list of external links: Tutorials (e.g., NIH 3D Print Exchange. GitHub repository of 3DP-Jmol (link to documentation and issue tracker). Proteopedia help pages for embedding 3D-printable content. List of major printing services provider - maybe a link on Gmaps that would search for 3D printing services in the user region?

If you print a model from Proteopedia, please share photos and feedback — let’s 3D print the whole Proteopedia!

References

- ↑ Howell ME, Booth CS, Sikich SM, Helikar T, van Dijk K, Roston RL, Couch BA. Interactive learning modules with 3D printed models improve student understanding of protein structure-function relationships. Biochem Mol Biol Educ. 2020 Jul;48(4):356-368. PMID:32590880 doi:10.1002/bmb.21362

- ↑ Răzvan-Ştefan B, Laura Nicoleta P, Mihășan M. Impact of 3D-printed molecular models on student understanding of macromolecular structures: a compensatory research study. Biochem Mol Biol Educ. 2025 Jul-Aug;53(4):358-369. PMID:40214166 doi:10.1002/bmb.21902

- ↑ Smith DP. Active learning in the lecture theatre using 3D printed objects. F1000Res. 2016 Jan 13;5:61. PMID:27366318 doi:10.12688/f1000research.7632.2

- ↑ Srivastava A. Building mental models by dissecting physical models. Biochem Mol Biol Educ. 2016 Jan-Feb;44(1):7-11. PMID:26712513 doi:10.1002/bmb.20921

- ↑ Larsson, C., Tibell, L.A.E. Challenging Students’ Intuitions—the Influence of a Tangible Model of Virus Assembly on Students’ Conceptual Reasoning About the Process of Self-Assembly. Res Sci Educ 45, 663–690 (2015). DOI: 110.1007/s11165-014-9446-6

- ↑ Da Veiga Beltrame E, Tyrwhitt-Drake J, Roy I, Shalaby R, Suckale J, Pomeranz Krummel D. 3D Printing of Biomolecular Models for Research and Pedagogy. J Vis Exp. 2017 Mar 13;(121):55427. PMID:28362403 doi:10.3791/55427

- ↑ Mihasan M. A beginner's guideline for low-cost 3D printing of macromolecules usable for teaching and demonstration. Biochem Mol Biol Educ. 2021 Jul;49(4):521-528. PMID:33755300 doi:10.1002/bmb.21493

- ↑ Segarra VA, Chi RJ. Combining 3D-Printed Models and Open Source Molecular Modeling of p53 To Engage Students with Concepts in Cell Biology. J Microbiol Biol Educ. 2020 Dec 21;21(3):21.3.72. PMID:33384761 doi:10.1128/jmbe.v21i3.2161